It took a while after starting Chandi Chocolates to get to the point of being able to work with cacao closer to the source. Once I discovered cacao butter, I had to learn more: why are there so many different cacao products? Paste, butter, powder, nibs… how would I use them?

I learned that the cacao plant produces large seed pods. The seeds are scooped out, fermented, dried and crushed to make the product known as “nibs”. Reeling with this newly acquired information, aghast at how far removed “chocolate” is from the plant, I decided to at least make the attempt to produce a bar that was closer to the source.

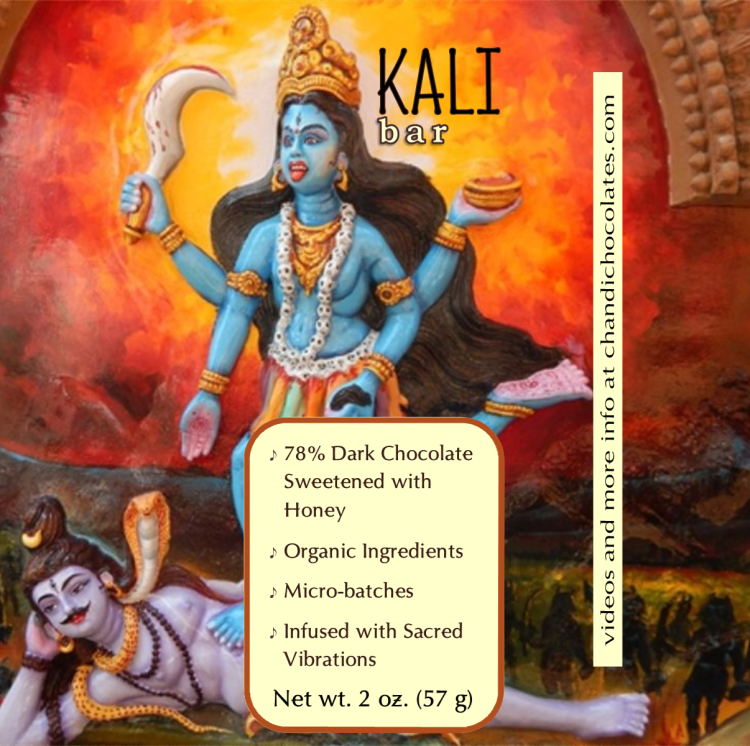

First, starting with paste and the Kali bar, it occurred to me that the reason there were so many different cacao products was to better manipulate the fats, solids and flavors to produce unique chocolates. At that point, I developed a new appreciation for chocolate and starting tasting a variety of “boutique” chocolates. And then I learned there was a machine that was small enough to use at home in which I could process the nibs into chocolate myself: I had to try it.

Success was not immediate: the commercial kitchen that I had started using as the sale of Guru bars increased was not far from my home, but far enough that going back and forth and even finding time to run the refiner was a challenge. The nibs had to be warmed up and introduced slowly into the little machine – which maxed out at 7-1/2 pounds and not the advertised 8. I learned the hard way – nibs spinning out splattering the shelves, walls, counter – that you cannot simply pour the whole into the machine and walk away.

My first Chandi bar was made with cane sugar. A perhaps little known fact is that sugar doesn’t dissolve in chocolate. Instead, the refiner breaks down both substances until the particles of sugar and cacao are so fine that the tongue cannot distinguish them as separate. I followed quickly with a Shiva bar which substituted erythritol before erythritol got a bad name and I discontinued the bar.

Once the refiner portion of the machine – the knob tightened to its maxium – has done its thing for 4 to 6 hours, the conching process can begin. This simply involves loosening the knob and allowing the chocolate (for it is chocolate at this point) to develop its unique flavor in the spinning drum. Tasting every hour is recommended.

I would lay awake at night doing the math: should I start at 11pm and get up at 5am so I could start tasting? Or maybe start at 6am, which meant getting there at 5am to warm and load the machine, then get out of work at lunchtime to start tasting? And then how long should it run?

A couple of batches into trying to fit the refining/conching process into my full-time work schedule, I had started at the “wrong” time and had to pour the unfinished chocolate into molds and melt it down again the next day to resume the process.

Now I wish I had noted exactly “when and for how long” because the flavor of that batch was something like a miracle: How on earth could something bitter, sometimes chalky, sometimes sticky could become silky smooth with a subtle flavor of berries?

<<<<< to be continued >>>>>